Magnetic Particle Testing

Magnetic Particle Testing

This method is suitable for the detection of surface and near surface discontinuities in magnetic material, mainly ferrous steel and iron.

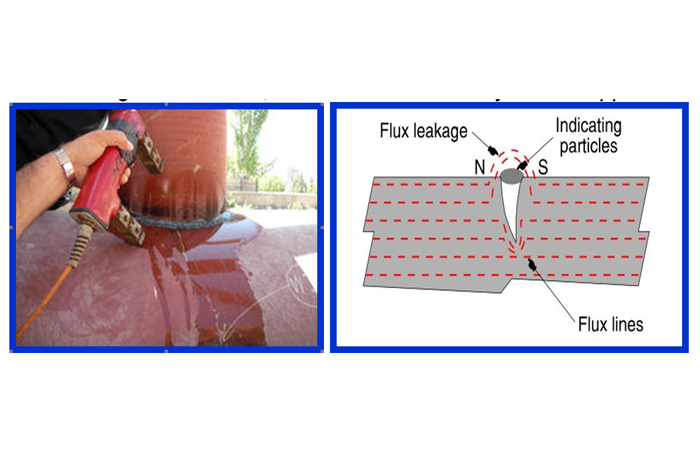

The principle is to generate magnetic flux in the article to be examined, with the flux lines running along the surface at right angles to the suspected defect. Where the flux lines approach a discontinuity they will stray out in to the air at the mouth of the crack. The crack edge becomes magnetic attractive poles North and South. These have the power to attract finely divided particles of magnetic material such as iron fillings. Usually these particles are of an oxide of iron in the size range 20 to 30 microns, and are suspended in a liquid which provides mobility for the particles on the surface of the test piece, assisting their migration to the crack edges. However, in some instances they can be applied in a dry powder form.

In the direct method high amperage current is passed through the subject and magnetic flux is generated at right angles to the current flow. Therefore the current flow should be in the same line as the suspected defect.