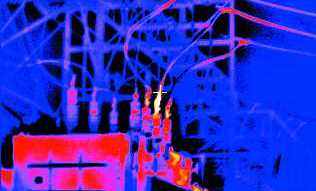

Infrared- Thermography

The infrared camera evaluates and converts heat energy into meaningful temperatures. Components in various states of failure will emit more heat as a direct result of more energy dissipated into the component.

This extra energy is caused by increased friction in mechanical devices, and higher resistance in electrical devices. For the following equipment thermography survey can be carried

| Application | Conditions Detected |

|---|---|

| Drives/Conveyors, Pillow Blocks, Couplings, Gears, Power Transmission Belts, Pulleys, Shafts. | Overheated bearings or rollers, misalignment of shaft, pulley or coupling, lubrication failure uneven pressure. |

| Motors | Overheating of windings and bearings, blockages in cooling passages, friction, damping, material deformations, brush contact problems, rotors |

| Pumps /Compressors /Fans /Blowers | Overheated bearings, high compressor discharges temperature, high oil temperature, and broken or defective valve. |

| Heavy Duty Equipment - Tires, Bearings, Brakes, Hydraulics, Kiln | Overheating brakes, tires, bearings, pulleys, gears, gear or pulley misalignment, and blockages in hydraulics. |

| Mechanical Drive Turbines and Steam Turbine Generator Units, Gas Turbine, Exhaust Ducts | High lube oil temperature, high bearing temperatures, faulty stop/control valve operation, uneven metal temperature, leaking shaft seals, gas turbine firing conditions, including deterioration in firing chambers, cross firing tubes. |

| Valves: Shutoff Valves, Relief valves, steam traps | Leakage, Blockage. |

| Electrical inspections and electrical equipment | Unbalanced loads, Eddy current heating, Improperly sized fittings, Broken strands; Bad connections, breakers, fuses; Overloaded conditions, Motor Control Centre components, Distribution lines, Cable trays/conduits |